What are dowel pins?

Dowel pins are a type of industrial fastener which is used to join items together. They are steel pins which are inserted into receiving holes, to hold the parts of an assembly together by using friction. Dowel pins can hold two or more parts together in a fixed alignment using a very tight fit to keep them firmly in place.

Dowel pins are parallel pins which can be ground and precision hardened so that they can be perfectly aligned and accurately located in order to obtain an extremely tight tolerance limit within the drilled and reamed hole. They are manufactured to very accurate tolerance limits to ensure exact location and alignment.

Dowel pins are normally made of hardened or silver steel and are available in a range of different sizes, Standard sizes range from 1-mm to 25-mm with standard lengths from 3-mm to 120-mm. However, custom sizes can be produced as required and at Special Screw India Inc., we have the technology and equipment available to produce whatever size of dowel pin you require to the highest standards of precision.

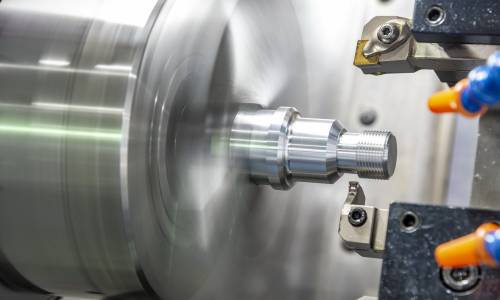

OUR WORK

Here is a small selection of typical dowel pins we have manufactured

Pointed Dowel Pins

Dowel Pins

Clevis pins

What are dowel pins used for?

Dowel pins are frequently used in the aerospace and automotive industries and in furniture construction. They can be used in many different applications, and sometimes they are used as location pins.

What are the different types of dowel pins available?

Dowel pins can be plain, with no threading. Or they can be tapped, with an internal thread in either metric or standard imperial measurements.

Some dowel pins have one chamfer end, and one dome end, which are normally made of unhardened steel. Larger diameter pins are sometimes manufactured with chamfers at both ends.

Dowel pins can be plain, with no threading. Or they can be tapped, with an internal thread in either metric or standard imperial measurements.

Some dowel pins have one chamfer end, and one dome end, which are normally made of unhardened steel. Larger diameter pins are sometimes manufactured with chamfers at both ends.

Some dowel pins are made of hardened or ground steel which is obtained through a variety of processes including quenching in water or oil and passing through induction chambers. When steel cools quickly the carbon atoms are frozen and trapped within the shrunken iron crystals. This produces a very hard substance, but one that can not stand much impact or shock. Some dowel pins are fully hardened to 60+/- HRC and are ground to m6 limits.

Stainless steel dowel pins are unhardened as it is not possible to make stainless steel thermally hardened. These are non-magnetic and do not rust, corrode. or stain. and they have a relatively high-pressure rating. Stainless steel dowel pins are recommended for marine and subsea applications and are also frequently chosen for food preparation and hygienic applications.

In some blind hole applications, it is necessary to be able to extract the dowel pin. Sometimes called pull pins, these dowel pins are made to be removed, and extractable dowel pins have an internally tapped thread. A dowel pin extractor tool makes removing a dowel pin fast and easy and the pin can be reused. The tool is threaded into the extractable dowel pin and using a slide hammer principal, applies force to remove the pin. In small diameter pins, the threading may be smaller than British standard in order to maintain a thicker wall and so decrease the possibility of cracking.

A ground flat for air release is normally recommended for use in blind holes.

Some dowel pins have straight or spiral grooves cut into them to create a greater surface area so improving their holding power. Some are knurled to provide a better grip and some pins are tapered.

For moving applications drive pins with an interference fit are commonly used and these need to be driven into place. For light fastening jobs Escutcheon pins which can be hammered into place are commonly chosen.

To help you to decide which type of dowel pin is most suitable for your needs, visit our work now or contact the experts at Special Screw India Inc., and we will be happy to assist you.

Email Contact or call +86-755-29898221

More Special Fasteners

We manufacture a range of special fasteners for a wide range of applications.