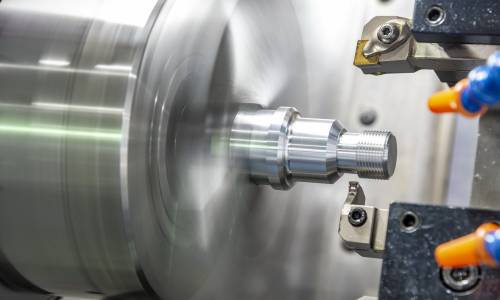

Stainless Steel Turned Parts

Thanks to the specialist in-house equipment at Special Screw India Inc., our experienced team is able to create bespoke stainless steel turned parts to even the most detailed of specifications.

If you’ve been struggling to find exactly the right components for a project, all you need to do is send us your detailed requirements and our specialists will create perfect stainless steel turned parts for your purposes.

Using the most up to date manufacturing technology, we can replicate precise measurements time and time again, creating accurate fasteners that you will not be able to find anywhere else.

WHY CHOOSE STAINLESS STEEL MACHINED PARTS?

Stainless steel has extremely high resistance to corrosion which makes it ideal in situations where moisture is present. Stainless steel can present resistance to saltwater depending on the grade used, making these an ideal choice for a number of industries including marine environments.

Stainless steel is also known for its strength, making it a popular choice in the building and construction industries. In addition to its strength, stainless steel can also be polished for aesthetic reasons.

Therefore, stainless steel parts are strong, pleasing on the eye, and with their corrosion resistance are likely to last longer than many alternatives regardless of how these parts are used.

Material grades for stainless steel and machined parts include:

- 17-4PH/ S17400

- 303

- 304

- 316

- 316L

- 410

- 413

- S31803 DUPLEX/ 2205

- 321

- S32760 DUPLEX

- 660

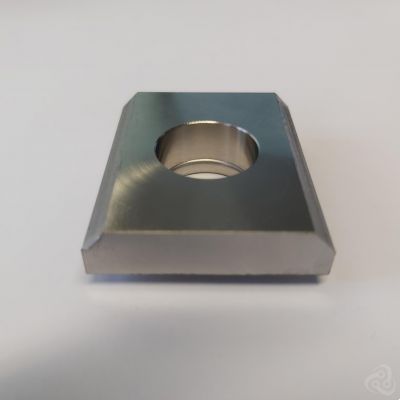

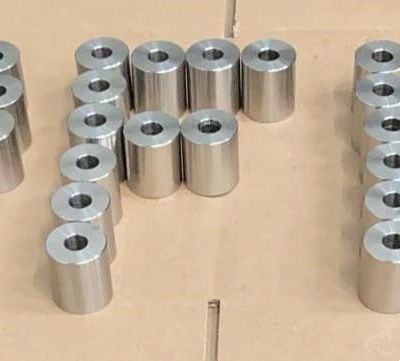

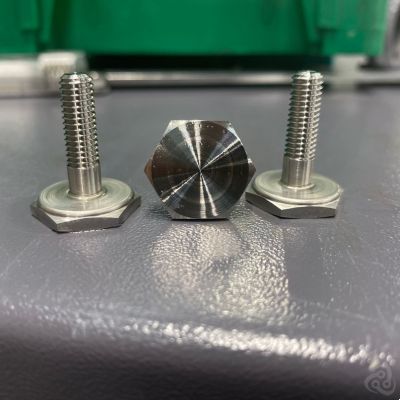

OUR WORK

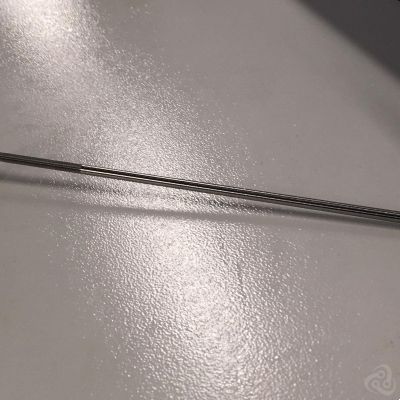

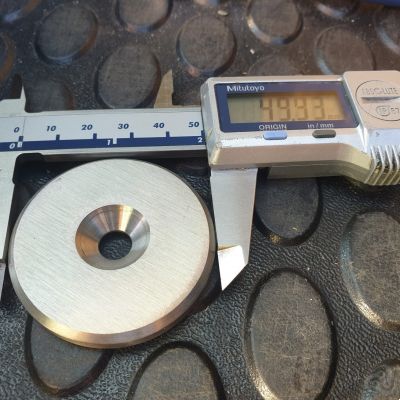

Here is a small selection of typical stainless steel turned parts we have manufactured

Washer

Tri head security fastener

Tri head screws

Threaded collars

Stainless washer

Stainless steel parts

stainless steel nozzle

Stainless Steel lugs

Stainless Steel Button Washers

Stainless screws

Stainless custom part

Sector: Medical application

Spacers

Socket cap screws

Socket cap screws

Shoulder bolt

M5 316 stainless steel nut

M3 Threaded

M16 hexagon nut

Locking cam

Lock nuts

Hosetail Fitting

High Tensile Bolt

Hexagon head screw

Extra long socket cap screws

Dumbell

Control knob

What are Stainless Steel Turned Parts?

Thanks to our extremely precise CNC (Computer Numerical Control) machines which utilise CAD-CAM (Computer Aided Design and CAM Computer Aided Manufacture) technology, experienced members of the Special Screw India Inc. team can input exact measurements and designs that will then be produced with absolute accuracy.

No matter what purpose you’d like your custom steel turned parts to serve, or whether you need dowel pins, grooved pins, grooved shanks, set screws, pointed bolts, dog point screws, cone point screws or something different entirely, we’ll create components to the exact measurements you provide.

However complex your design, the machines’ use of delicately calibrated lathe heads, bar fed mechanics, driven tooling and pressure coolant will produce just what you require.

Email Contact or call +86-755-29898221

More Turned & Machined Parts

We manufacture a range of turned and machined parts for a wide range of applications.