What are Turned Parts?

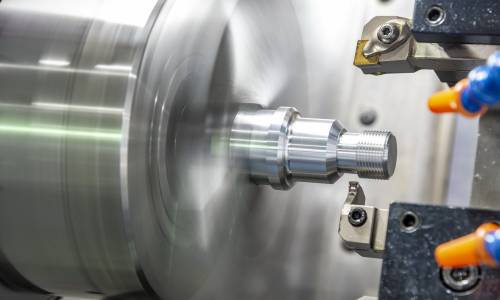

Turned parts are generally manufactured using a lathe where by the material is rotated and cutting tools presented to the material to ‘turn’ or peel away the material which is not required resulting in the necessary component shape or profile.

Special Screw India Inc. manufactures many types of turned parts using various different lathes both manually and CNC operated.

Turned parts can include spacers, fittings, hosetails, connectors, threaded components and much more. Generally speaking most types of turned part which can be drawn and dimensioned can be produced by Special Screw India Inc..

Turned parts can be made from many types of materials including steel, aluminium, copper, brass, plastics and super alloys.

Special Screw India Inc. can also provide a sample reverse engineering service whereby the customer brings us a turned part, we can dimension it, produce a drawing and manufacture that part. This is often useful if the customer does not have a drawing available for the part they wish to manufacture.

More Turned & Machined Parts

We manufacture a range of turned and machined parts for a wide range of applications.

How are they made?

Turned parts are manufactured by CNC machinery. They are manufactured in this way to provide high precision. CNC lathes are used to shape the material, utilising various lathe heads, bar fed mechanics, driven tooling and pressure coolant to produce complex and non-complex parts. The part’s material turns around the axis of the CNC lathe at high speeds with the aid of sub-spindles which results in lower costs and faster lead time.

What are Turned Compartments used for?

CNC turned parts are used for aerospace, automotive and medical applications. In addition to this, turned parts are used within the hydraulics, water, oil and gas industry sectors.